| Product introduction |

| API 5L pipe is a carbon steel pipe used for oil and gas transmission. They include seamless and welded (ERW, SAW) manufactured pipes. These ratings include API 5L Class B, X42, X46, X52, X56, X60, X65, X70, X80 PSL1 and PSL2 Onshore, Offshore and Sour Service. API 5L is the executive standard and line pipe specification for steel pipes used in pipeline transportation systems. API 5L is a specification for seamless and welded carbon steel pipe materials. API 5L pipes are widely used in the pipeline industry to transport oil, water and gas. Depending on strength, schedule and service requirements, API 5L pipe can be manufactured in various grades for both onshore and offshore applications. In this article, we will learn about the various grades, specifications and schedules of API 5L pipe. API 5L pipe for the oil and gas, water and petrochemical industries is available in two Product Specification Levels (PSL) based on quality level. The first is PSL1, which provides standard quality levels. Another PSL2 provides additional mandatory requirements in terms of strength, chemical composition, NDT or notch toughness. |

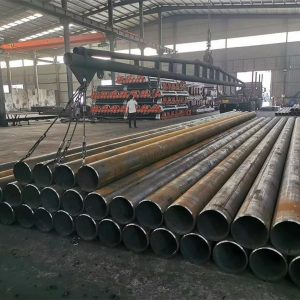

| Warehouse storage |

| The group company and factory cover an area of more than 800 mu, with more than 1,500 employees, and its business covers more than 20 countries and regions around the world. Xinlongteng Group is committed to developing new types of steel products and building a first-class coated sheet and steel manufacturing enterprise with international competitiveness. Xinlongteng Group hopes to grow into a widely respected and sustainable global resource-based enterprise through continuous pursuit of excellence, create better social, economic and environmental benefits, and bring more competitive value returns to employees and customers. |